Speed-n-Feeds is written with the busy machinist in mind, it is a machining calculator that allows you to plan your machining approach in a calm environment either at the machining station or away from the mill

Feed-n-Speeds

What is it about?

Speed-n-Feeds is written with the busy machinist in mind, it is a machining calculator that allows you to plan your machining approach in a calm environment either at the machining station or away from the mill. The time estimator will allow to make decisions that will save you time.

App Screenshots

App Store Description

Speed-n-Feeds is written with the busy machinist in mind, it is a machining calculator that allows you to plan your machining approach in a calm environment either at the machining station or away from the mill. The time estimator will allow to make decisions that will save you time.

There are times when tool life will be sacrificed to meet schedule and there are times when a high quality surface finish is the deliverable. Referencing the Material Removal Rate for any given setup will allow you to maximize efficiency.

Features include:

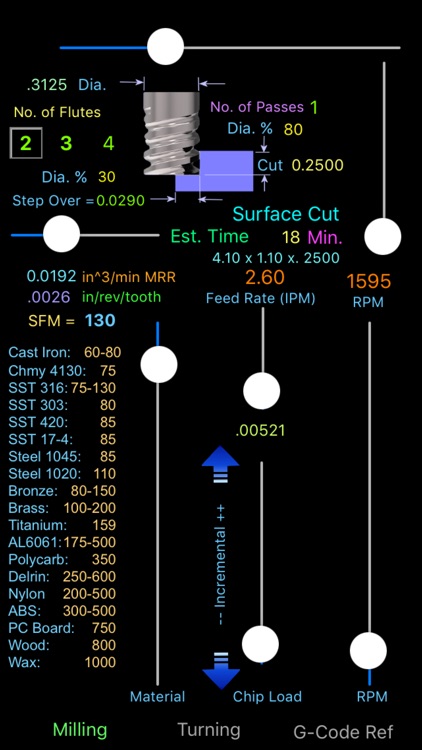

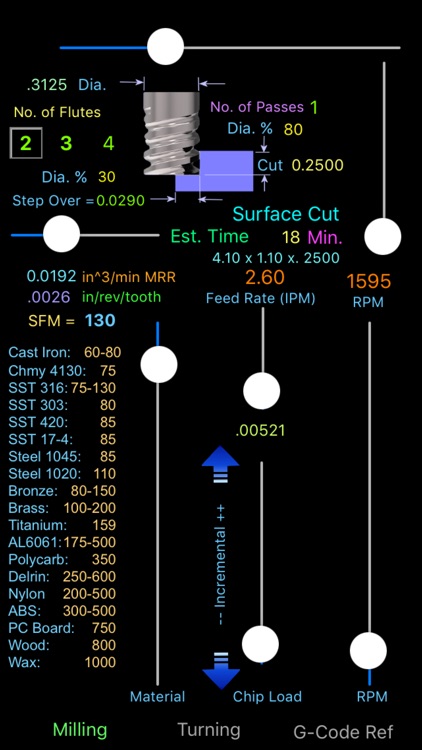

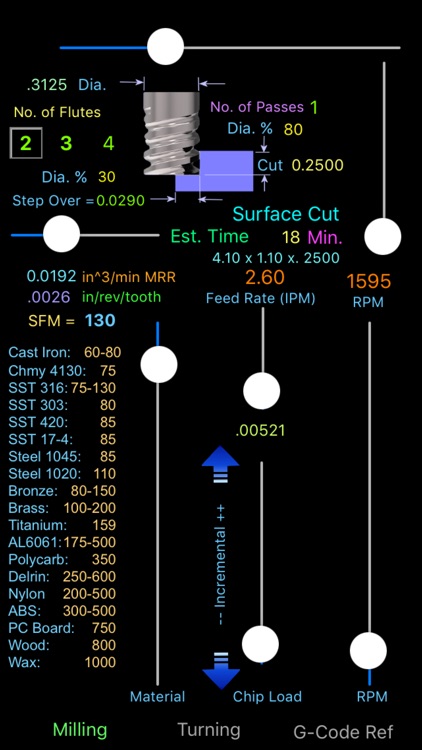

- SFM 60 – 1000

- Milling Cutter Dia .03125 – 1.000" (in 1/64ths)

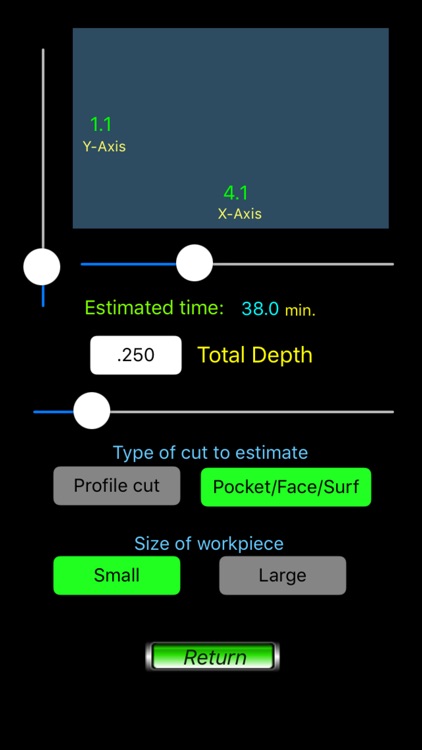

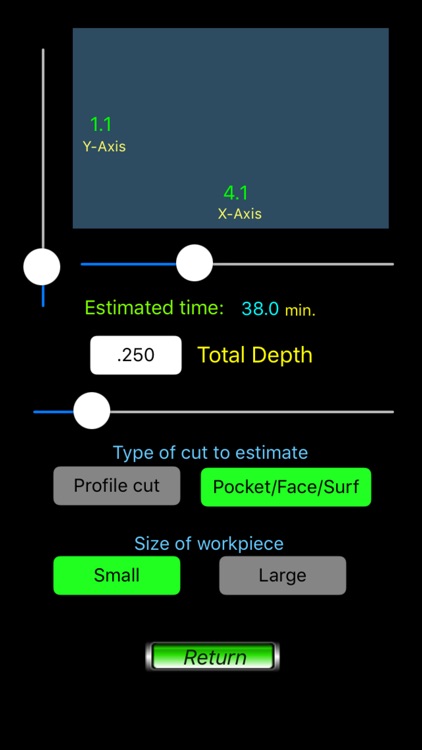

- X and Y area 36” x 48”

- Time estimate for Pocket, Face, Multi-surf or Profile

- Z depth number of passes 1 – 10

- 2, 3 or 4 Flute

- SFM for 19 common materials

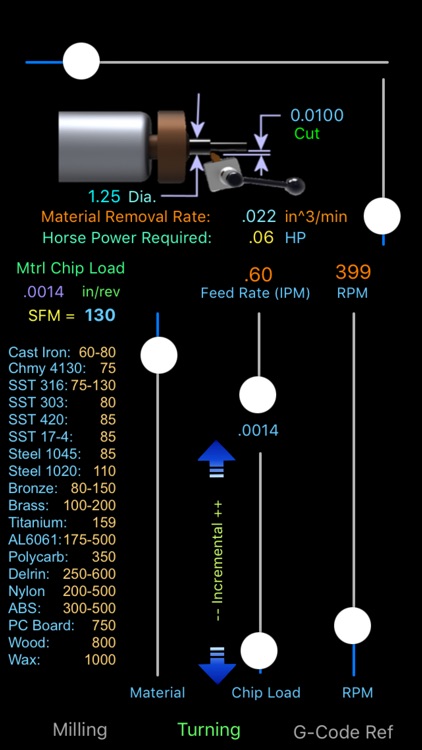

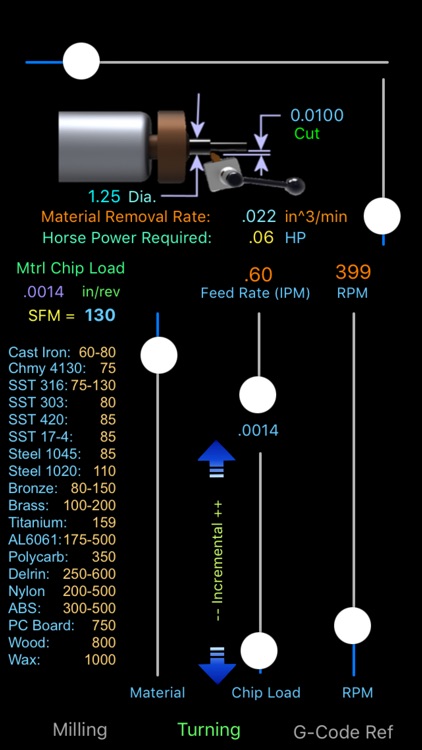

- Material removal rate in^3/min

- Feed Rate in/min

- Nominal Chip load

- Horsepower at Motor estimate for Lathe

- Lathe cut depth .001 to .100

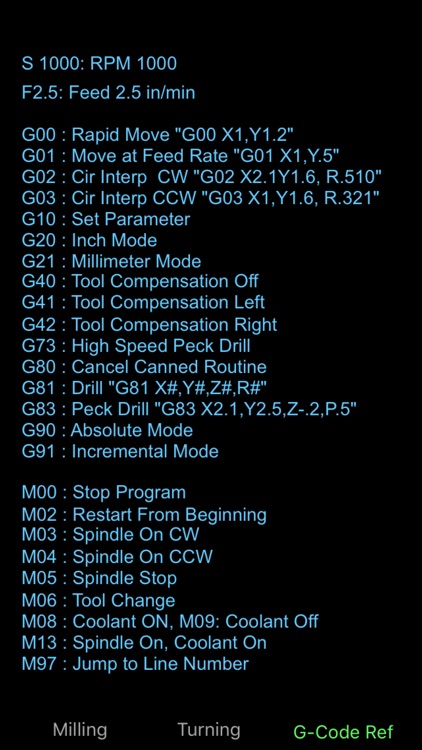

- M and G code reference (most often used codes)

Chip Load will be set to an estimated starting point for the current SFM value, the chip load value can be thought of as controlling surface finish, or how aggressive you push the tool.

You can change Chip Load, RPM, Horizontal Step, Number of Z-depth passes independently, however once you change tool Dia., or number of flutes, or Material, all sliders are set to a nominal number for that material and tool diameter.

You can easily explore Chip Load and RPM settings; then reset back to nominal by just tapping the Flute number again.

There is a manual entry option for the SFM and RPM in the milling screen; just tap SFM or RPM to enter a value manually.

The app will allow you to see numbers outside convention, and the nominal values may need to be adjusted to fit the surface finish you need, or correct for the tool sharpness, or the material granularity you are milling.

The Feed Rate slider is dynamic but not active to user input, the Chip Load slider is the preferred adjustment when considering feed rate or surface finish.

The Speed-n-Feeds app is also a very handy tool for the smaller machine shop where you run jobs on your CNC mill and run the manual mill for smaller jobs and turn a lathe job from time to time.

The business owner dealing with job estimates can also benefit from this mobile app to be sure they are committing to turn around times that are feasible, some of those harder materials take time to mill material away, too fast and the parts warp and are out of spec.

One of the benefits of this dynamic interface is the ability to visualize the relationships between Materials, Cutter Diameter, Material Removal Rates and Chip Load. As you change the Cutter Diameter you can watch the RPM and Chip Load sliders move into position for the material you have selected, you see the milling Time Estimate update in real time.

You will appreciate the time saving benefits of those larger diameter 4 flute cutters.

The app formulation is setup for HSS mill cutters, to use carbide cutters you can adjust the Chip Load, which will increase the feed rate. The app is meant to be a handy reference tool giving you the ability to estimate cycle time before you program your tool paths and assist you in planning your machining approach. We realize Safety is the first priority..

AppAdvice does not own this application and only provides images and links contained in the iTunes Search API, to help our users find the best apps to download. If you are the developer of this app and would like your information removed, please send a request to takedown@appadvice.com and your information will be removed.